Capabilities

Design & Development

Custom Filter offers complete in-house engineering services including filter design, prototyping, manufacturing and filter testing for projects of all sizes and complexities (concept-to-reality).

Our experienced product development team uses state-of-the-art tools including CAD (SolidWorks), solid modeling, validation software, and rapid prototyping tools.

Our design team prides themselves on providing quick, innovative and simple solutions for unique and complicated filtration applications.

Custom Filter validates design work by prototyping filters during the design process to illustrate innovative concepts, product performance and to gather customer feedback.

Custom Filter’s product design group, along with our quality system, ensure that filter construction is carefully designed, documented, validated and cost effective to manufacture.

We understand that speed, creativity and manufacturing proficiency are critical to our long-term success.

All Capabilities

- HEPA & ULPA

- Pressure Drop / Resistance

- Efficiency

- Leak, Thread & Smoke

- Particle Counters

- Photometers

- ATI

- Automated, Custom Built, Test Rigs

- Lot Control (Serial Numbering & Data Base Collection)

Custom Filter offers extensive testing and central database collection systems using a wide variety of manual, semi-automatic and automatic test rigs. We can test your filters to the appropriate filtration standard required for your specific application. If requested, we can test 100% of the product we manufacture and provide the supporting documentation.

- Blade

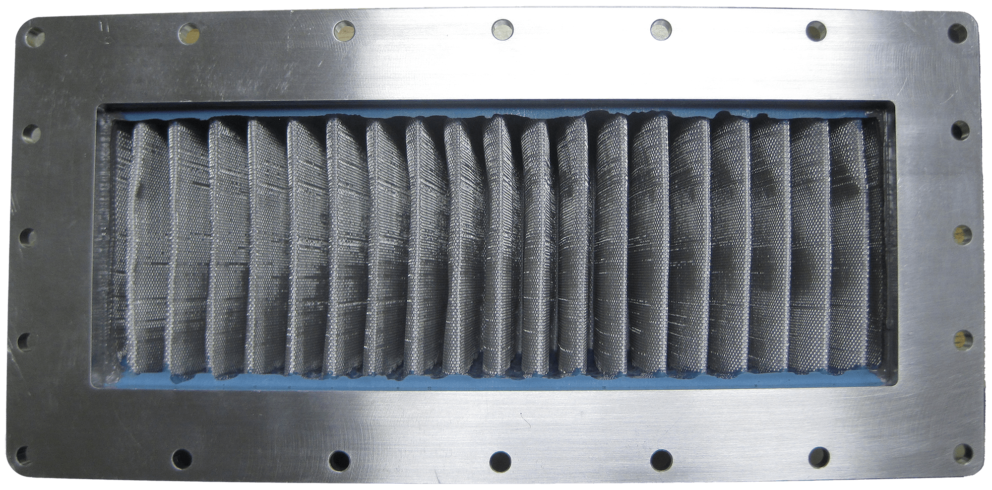

- Mini-Pleat Hot Melt

- Mini-Pleat Thread

- Rotary

- Hot Melt

- Thread

- Netting

- Over-the-Crown

Custom Filter manufactures high quality pleat packs in any shape, size or configuration using our state-of-the-art equipment. We can supply your organization with a wide variety of separation methods, pleat heights, multi-layered media, edge sealing, sonic welding and pre and post cutting options using one of our seven (7) pleating lines.

- Waterjet

- Steel Rule Die Press

- Flash Cutter

- Multi Press

- Ultrasonic

Custom Filter can provide die cutting in any shape, size or configuration using our state-of-the-art equipment. Our water jet equipment, combined with CAD interface, is designed to provide high-speed precision cutting of flat, layered or pleated media. If you are looking for prototypes, low- or high-volume production, or precision cutting of high valued materials, we have the solution!

- Manual

- Semi-Automatic

- Automatic

- Cut with Sealed Flange

- Rotary Stitch

Custom Filter offers ultrasonic welding using various manual and fully automated lines, depending on volume. We can weld and cut simultaneously, which provides a hermetically welded seal around the entire perimeter of the part. We can cost effectively produce short and long runs of difficult to weld materials, including thick, multilayered composites and odd shapes.

- Marking

- Assembly

- Robotics

- Ultrasonic Welding

- Gluing

- Pleating

- Testing

- Spin Welding

Custom Filter can design, engineer and build a production line customized and dedicated to your specific product or requirements.

- Insert Molding

- Injection Molding

Custom Filter offers injection and insert molding expertise and can efficiently design, build and manufacture filters using unique methods and techniques to tackle challenging applications.

- Molecular/Carbon Drop

- Snow Filling

- Automated Dispensing

- Vibrating Tables

- Bulk Loading

- Volumetric Filling

- Carbon/Molecular Loaded Media Conversion

Custom Filter has manual and automated equipment to load both small and large filters using snow filling equipment that will uniformly dispense the molecular granules to prevent channeling. Larger filters can be packed solidly using our vibrating shaker tables and bulk filling equipment.

We also offer a wide variety of high tech molecular impregnated/loaded media and can pleat, die cut, ultrasonically weld or fabricate the media to meet your needs.

- Metal Engraving

- Hot Melt Ink

- Pad Printing

- Label Applicators

- Laser Jet

- Hot Stamping

Hot Air Welding

- Netting

- Synthetic Tubes

Sewing

- Single needle

- Double needle

- Surger

- Ultrasonic stitch

- Roller Coaters

- Ram Tables

- Lamination

- Shearing

- Spot Welding

- Spin Welding

- Spin Casting

- Centrifugal Casting

- Cut-to-Length Cutting

- Metal Rolling

- Bag Sealing Equipment

Adhesives

- Adhesive Urethanes

- Moldable Urethanes

- Hot melts

- Plastisols

- Adhesive Plastisols

- PURs

- Cyanoacrylates

- Polyvinyl Acetates